Tenova Bateman’s LiSX technology [Awesome video here]

Get ready, an attempt will soon be made to illuminate these two groundbreaking (actually neither breaks ground) technologies. A detailed, technical assessment is beyond the scope of this article. Essential in understanding what each technology is tasked to deliver, is understanding the shortfalls of brine harvesting and hard rock mining. Each suffer from a number of challenges; large upfront capital outlays, long operating cycles, (brine), inferior recoveries, unattractive environmental footprints, energy intensity, operational inflexibility and weather related risks. The new age of technology promises to cut operating cycles to hours, be greener and less energy intensive. Commercial scale recoveries are expected to be 99.9%, leading to lower, more predictable operating costs and far less waste (virtually no tailings).

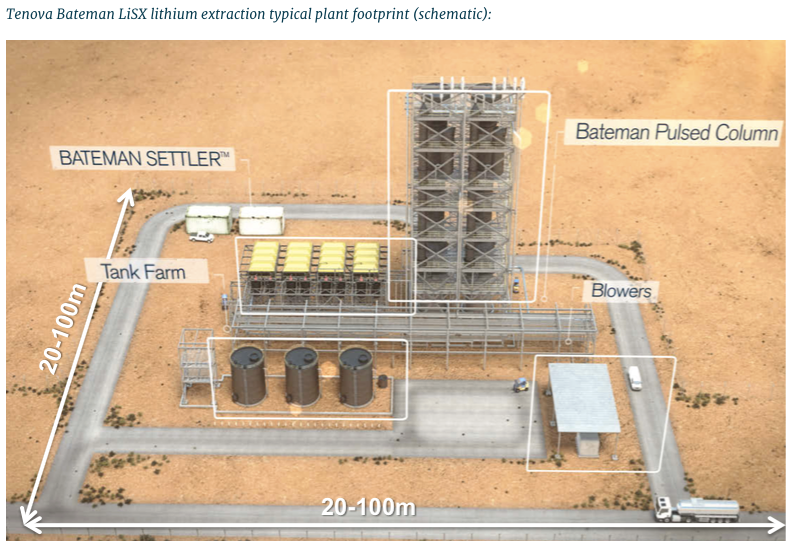

Tenova Bateman’s LiSX technology achieved spectacular results at bench scale with 100% Li extraction at robust purity,lithium chloride solution (>99.9%). The company continues to conduct Pre-Feasibility level design work on Pure Energy’s Clayton Valley. Tenova’s LiSX solvent extraction technology is effective on a much wider range of lithium containing material. Quote, from a Tenova Bateman marketing brochure,

“Tenova Bateman Technologies offers advanced solvent extraction solutions and proprietary technologies for the mineral and bio-process industries, complimented by in-house laboratory and pilot plant facilities….” “Aqueous feed solution is mixed with customized solvent in which lithium ions are preferentially absorbed, loading the organic solvent with lithium. The loaded solvent is separated from the aqueous brine and stripped of lithium by adding an appropriate acid, producing a lithium salt and barren solvent to be recycled / reused.”

“In salar operation, waste streams are suitable for re-injection, eliminating environmental impacts. The LiSX process is fully effective on aqueous solutions containing lithium concentrations as low as 20 ppm, with recoveries in excess of 99%. The LiSX process is versatile and can be rapidly reconfigured to produce different lithium end-products at exceptionally high purity.”

I couldn’t have said it better myself. How can I explain this technology to my intelligent, but possibly less technically oriented readers? Enter stage right Mr. Andy Robinson, Ph.D. COO of Pure Energy. Andy, can you please explain, in layperson’s terms, the above quoted paragraphs? Thank you.

Brine (salty groundwater) is pumped from underground and filtered to remove magnesium and calcium. It’s then mixed with a proprietary solvent that selectively removes only the lithium. The lithium in the brine combines with the solvent, even at low concentrations (as low as 20 ppm). The solvent is then moved into settling tanks where it is collected. The lithium is removed from the solvent, and processed into high purity battery materials such as lithium hydroxide. Now that the solvent has no remaining lithium in it, it’s available to be recycled and used again. The process is continuous, takes less than a day, and the lithium-free brine would be re-injected back into the ground, providing a uniquely sustainable, low energy intensive, and truly green solution.”