Pat Gelsinger: Yes. And the two things in the Q4 to Q1 numbers on IFS, one is the – I’ll say the natural ending of our traditional packaging volume. So that affects Q4 as we go into Q1. And obviously our focus there isn’t doing I’ll say traditional packaging. You know, that’s best supplied by OSAT vendors, but we were in a unique position to help our customers as we went through the COVID cycle. All of our packaging focus going forward, is advanced packaging where our technology is differentiated, the margins are good. And as you saw, we just announced the New Mexico facility, as the first major advanced manufacturing facility on U.S. soil. A lot of excitement from that from customers across the world. Also, we had our foundry equipment business, which was another factor Q4 to Q1, very consistent.

With the profile that you might’ve heard from people like ASML, right? As they saw the quarter-to-quarter implications on the equipment business. So I’ll say Q4 to Q1, all explainable in those contexts. The business we’re winning 18A foundry customers, Intel 3 packaging, it takes quarters for that to materialize and for wafer customers’ years. And that’s why we said lifetime deal value is probably the best metric that we can give you to help you understand the nature of that business as it’s growing. And as I said, we saw a big uptick from our prior update to this one. Obviously we need to, as your question suggests, get to a much bigger number. And that’s exactly what we’re going to do. We’re now well underway. We’re seeing healthy growth in lifetime deal value.

We’ll be giving you periodic updates on it as a good metric of seeing how rapidly that business is growing for us. And I’ve emphasized that number is just external foundry, right? Our internal business is what’s going to be driving the factory build out. And that really gives us the scale to then start adding these additional external customers to it. Those deals, as we say, they could be a year or two, or they could be multiple years in length. There’ll be a varying contract length associated with them. And we just want to give some visibility, transparency to the business and a rapidly growing lifetime deal value is a good way for us to give you some characterization of that business outlook. Finally, I want to see you on February 21. We’re going to hold a big industry ecosystem event, our IFS direct connect and meeting with the ecosystem, our customers, but we’re inviting analysts to listen in to the great conversations we’re going to have and the disclosures that we’ll be giving there.

John Pitzer: Thanks Vivek. Jonathan, if you have time for one more question, please.

Operator: Certainly. One moment for our final question for today. And our final question for today comes from the line of C.J. Muse from Cantor Fitzgerald. Your question, please.

C.J. Muse: Yes, good afternoon. Thank you for squeezing me in. I’ll combine both my questions into one. Typically, you know, in a manufacturing transition, you take on one, maybe two kinds of technical challenges. Here at 18A, you know, you’re taking on backside power, gate all around and high in A. So, we’d love to hear kind of maybe some of the struggles you’ve seen, how you’ve worked through them, and what kind of feedback you’re getting from customers in all three of those and kind of the confidence on delivering the goods in the timeline that we set out? Thank you.

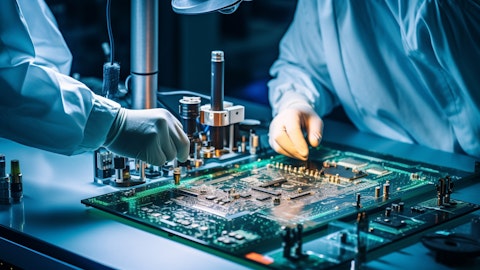

Pat Gelsinger: Very good. So let me characterize a little bit more carefully, because we’ve been trying to carefully manage the risk that we’re taking on. So first was the move into EUV. We began that with Intel 4 and Intel 3. And those, as we said, are high volume manufacturing underway done. So, we sort of took the risk of EUV off the table there. Backside power, right, we ran an internal node, something we didn’t disclose to external foundry customers. But we ran, many, many wafers using Intel 3, with backside power to go de-risk backside power, before we put it into Intel 20A and Intel 18A. So, we had a major step to de-risk backside power. And then of course, gate all around the transistor. So 18A brings those two together, backside power and the gate all around transistor.

But I’ll tell you, as we’ve been going through the development process. Backside power on 18A has been elegant, beautiful, high yield, very clean in its introduction into the process. And really the focus has been on the new transistor structure with gate all around. As customers are taking advantage of that now, as they’re starting to look at that, they’re really seeing great benefits from backside power. In some cases, almost as much performance benefit and significant area benefit from that. And gate all around transistors making good progress are 0.9 PDK that we delivered in Q4. And we’ll be having the 1.0 PDK in Q2 on track. And as I said, Clearwater Forest is the first product. And it’s now in fab on 18A, a huge milestone for us, both on the product side, as well as on the process side.

High-NA, the next generation of EUV is not part of 18A, right? That will be part of the next major node. We’ll talk more about that at the Intel Foundry Day, as we said on February 21, but we’re not introducing that as a risk factor into 18A. You know, it’s the EUV tools that are in production today that we’ve already de-risked as part of the Intel 4 and Intel 3. So, we think we’ve done a very careful management of risk. And we look at this all the time as we’re rebuilding our momentum. And as I said, overall, we are confident five nodes in four years. This was audacious. It’s been superbly executed, and we are on track to deliver it and get back to process, technology, leadership for both our products, as well as to establish a major foundry opportunity for the industry.