Mark Smith: A bunch of things to walk through here. First, this may be hit a little deeper on the demand environment that we saw in October. Can you just talk a little bit about maybe the consumer demand first? How much you saw that uptick. And did you see that — maybe what the impact was within your GunBroker business? I think that you said that — you quantified was at 14.7% sequentially, but that was the typical seasonality. Walk us through kind of what you’re seeing on the ground with consumers.

Jared Smith: So we would expect anywhere between a 5% to 6% increase and a gentle trend coming from September into October. This was a pretty sharp trend in that 14.7%. And that’s really because these events happened in the second half of October, it was really sharp incline after the events in Israel and Hamas that we saw the uptick. I think I answered only one of two of your two-part question. So, please repeat.

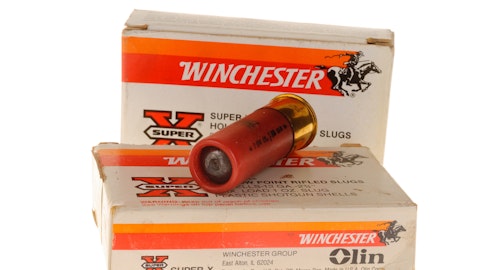

Mark Smith: Yes. Maybe just elaborate on that. Are you seeing demand — that demand, is that primarily on firearms or is that spread across firearms, ammunition and kind of other accessories?

Jared Smith: It’s spread across firearms and ammunition. And we’re certainly seeing an increase in ammunition sales on the platform, in those calendars. [Ph]

Mark Smith: Okay. And then the other piece of increased demand, maybe walk us through what you’re seeing from OEM customers for brass casings. So you’re seeing that demand uptick significantly in October as well? And I don’t know if there’s anything you can quantify around that.

Jared Smith: The issue being is that we’ve been sold out for quite a while, Mark. And until these presses come online, we’re not really wanting to take any new orders because we need to make sure that we’re getting the orders that we have on our books and that we are supplying our customers that placed orders back in March, April, and May, when we forecasted that this new press was coming online. So that’s our biggest issue. We could go out and take on 200 million, 300 million more brass case capacity, but the demand today that exceeds our output is really in a rifle case capacity, and that’s where we’ve had a shortfall in operational efficiencies.

Mark Smith: And then on that, as we think about these gun rifle process, these equipment issues that you had, where are we at today versus maybe where we were at the end of the quarter or mid quarter?

Jared Smith: Yes. Great question. So back in April, when we started to do the walkthrough of the new plant, we recognized that we didn’t have the redundancy that we needed. So, we bought additional presses, but those presses won’t come online until December. The press that went down, the parts showed up last week, we’re running and testing off this week. Once again, it’s not from a lack of demand, it’s not from a lack of everybody pulling together, trying to get this press up and running, this press was bought during COVID. Some of the parts were made during COVID. And the parts that are being made today are being made by the original equipment manufacturer versus when they outsource the parts for these. And so, we think we have a press that we can count on going forward. But the last three to four months of sending the parts back and forth and trying to get the parts to work has been a very frustrating experience for everybody on the team.

Mark Smith: And maybe the last one, and then I can go back into…

Jared Smith: One of the things that’ll help explain this press, this press is part of our pre form process and it feeds about six other presses downstream. So it’s not like a single press goes down and you just work around that press. It is the feeder press for our entire medium action line, which we have somewhere in 90 million to 120 million piece capacity on. So, it’s a big deal for us and has been.