David Zapico: Yes. I think that in that second half for Automation, in particular, we’re conservative on the input that we’re getting from our customers in the marketplace. And I think that for the entire segment, we’re forecasting it to be up low single digits. So we’re not out. If we just put in there what our customers are telling us it would be higher. So we’ve been — as a bit of conservative that we placed in it. And it’s largely from talking to customers and understanding their inventory levels and it’s the typical work that we do to set a plan for the year. And — it’s — we think the — we’ll see a positive second half as those orders, those backlogs are depleted.

Andrew Obin: Excellent. And just maybe a follow-on building on that. You talked about sort of increasing investment, but are there business units that need to start expanding capacity, where are you broadly in capacity utilization? And finally, as you are expanding capacity, what are you going to do differently about your supply chain and where you are putting this capacity versus maybe pre-COVID?

David Zapico: Yes. I mean in terms of supply chain, we did a lot of work to eliminate the risks from China, and we did it actually before COVID. So we were well positioned during it. And I think the — our supply chain is developing naturally around the different regions of the world and it’s not as China-centric because of that. So that’s 1 item. I think that in terms of capacity, we put significant capacity investments in over the past few years. We’re a low CapEx business. And it’s not — we don’t have to come to you and get away from our typical 2% of sales. We did it within our 2% of sales guideline. We put incremental capacity in our Mexican facilities. We put incremental capacity in our Malaysian facilities, we put incremental capacity in our Serbian facilities.

So I think we’re pretty — we have an asset-light business model and we can usually ramp up pretty quickly, and we have the flexibility to reduce cost very quickly. So that’s one of the advantages of the AMETEK model with our low CapEx environment. We can grow sales and adjust sales on the downside without big capacity investments without stringent investments when we downsize. So we’re in excellent position to grow and we’ve done all that work over the past few years or so, I feel really confident that we’re going to be able to keep up with the growth through the next growth cycle.

Operator: Our next question is coming from Brett Linzey of Mizuho.

Brett Linzey: Hey. Good morning, all. Congratulations to everyone. I wanted to come back to the pruning comment on Paragon. So you indicated you’re running down some of the less profitable areas makes sense. I guess in the context of the broader portfolio, as you continue to shift towards this higher growth, higher-margin areas, is there more pruning to do on the other side in the context of the total AMETEK portfolio?

David Zapico: This printing process is something that we do with just about every new acquisition. So this is not new. And Paragon is a little bigger business and we’re going to be careful with it. And but it’s something that we do all the time. So all M&A deals will go through this process. Paragon is going to be going through in the first half. And we look at our own portfolio and we do that kind of thing all the time. So yes, it can continue, and we’re pretty good at that portfolio rationalization things. Do you have another question, Brett?

Brett Linzey: Yes. And then just a second question on OpEx versus CapEx. I guess as you look at the customer spending environment for this year, and if you were to hone in on just those capital spending intensive businesses, have the planning assumptions or the tone changed in the last few months in that capital — the capital spending type businesses at all?

David Zapico: In the U.S., there’s a record number of projects from clean energy, power grid, semiconductor, they’re just at a different level than they’ve been before. And a lot of that is from the government spending and backing. So that’s largely continued. And at some point, it’s going to provide an optimistic playing field for a lot of people in the industry. And I don’t think we have that kind of upside built into our model right now, but it’s — there’s planning going on with those projects right now. And that particular dynamic about the U.S. spending is driving the typical projects. So we’re tracking to a very high number.

Operator: Our next question will come from Joe Giordano at TD Cowen.

Joe Giordano: Hey guys. How are you doing? So a lot of companies are seeing — have seen orders kind of decline organically for multiple quarters now. And predominantly, it’s all attributed to inventory adjustment and supply chain. And Harvey, anyone has said anything about underlying conditions not being fine. So just curious if one, if you would agree with that. And two, if it worries you that everyone is seeing order declines and no one is saying anything is happening other than supply chain adjustments.

David Zapico: It really doesn’t because it’s 100-year pandemic. I mean you saw what happened. The supply chains were broken. People put inventory in place. And as I just got done talking to the last call, the project business is so strong. So we have a similar view. We’re our businesses in health care, aerospace and defense, power and energy are performing well. They have a lot of projects. And we just think that we’re going to work off the inventory and then they’re going to be a return to more typical growth for the industrial market. I mean, at the end of the day, though, nobody knows. And if we run into a recession, we have good muscle member in that area. So we’ll be able to react as we always react and we can run our business appropriately.

And in fact, select businesses have already been doing that during ’23 margins in our automation business, those people did a great job of removing excess costs from the business. So we’re pretty good at reacting. But right now, we don’t see that. We see the inventory being worked off, mainly in our OEM businesses and looking toward the future, we’re optimistic with the number of new projects we have in the future.

Operator: Next question is going to come from Steve Bar with KeyBanc Capital Markets.

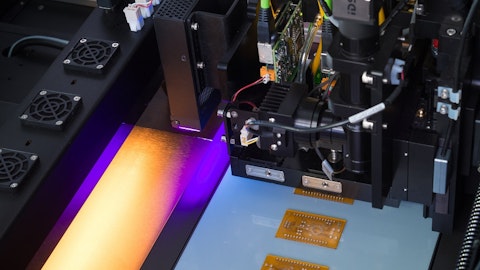

Steve Barger: Hey, good morning. For the semi business, you mentioned your exposure to optics, which is great, but does that extend to advanced packaging applications, which are expected to show strong growth rates for the next couple of years? And if not, is getting specific exposure there? Something the team is looking at for M&A?

David Zapico: Yes. We have a little bit of exposure to advanced packaging, but it’s spread across the business in different places, we’re selling some components. So that’s one of the items that our M&A teams are looking at, and we have exposure, but we’d like to have more.

Steve Barger: Okay. And then on the memory side, it seems like pricing is improving finally, and maybe fab utilization rates are starting to improve a bit. Is that translating into product inflection for you yet? Or is there still inventory that needs to be cleared on the memory side specifically?

David Zapico: Yes. I think that market on the memory side, that market is pretty much bottomed. So I don’t think there’s — when that ticks up, there’s going to be a — I think that’s immediately going to flow to the bottom line. I think the inventory there is mainly cleared out.

Operator: And our next question will be coming from Rob Mason of Baird.

Rob Mason: Yes. Good morning, and I’ll offer my congratulations as well, Bill. Dave, a lot of questions have been asked. I just circle back to the process business. You talked about that going to be up low single digits for the year. There’s a lot in there from a business mix and market standpoint. Could you maybe speak to anything that could outperform that low single digits or anything that would stand out? And just for clarity, say what is the actual process industry exposure there now?